How We Work

Leather Production Steps

Desalting is the removal of salt from the salted hides, the hides are passed through a circular machine; the salt is removed and collected in a conical vessel and desalted hides come out from the front of the machine.

The skins and hides are received mostly in the wet salted conditions in the tanneries. After desalting, soaking operation is done in which the salt is removed and the goods are dehydrated to their original condition. In this process, the adhering blood, dung and other soluble protein such as albumin and globulin are also removed. Soaking is normally performed in drums.

We do green fleshing here to remove extra fat, better open up the hides and reduce wrinkle effect. By green fleshing chemical later chemical penetration is made easier and we also get some area gain.

Primary objectives of the liming process are

* To remove the hair and flesh

* To open up the fiber structures of the skins and hides

* By Suitable plumping and swelling

Apart from these, a part of the natural fat or grease and other unwanted proteins such as sweat glands, blood

vessels, nerve tissues etc are also removed during the liming operations. The important properties expected in the

final leather can be better controlled in liming process

SLW has special Italian hair save machines by which hair is removed during liming process and is not discharged into

the effluent thus saving the environment. Further SLW has lime recycling process by which liming floats are recycled,

this reduces load on effluent treatment plant. SLW is also recycling the soaking water.

After liming, fleshing is done by fleshing machine to remove unwanted flesh Leather is weighed again. SLW have four fleshing machines

After washing of the limed pelt to remove lime from the surface, they are delimed with mostly ammonium salts and special organic and in organic acids to bring down the pH to 8.0-8.5

The important objective of this process is to purify the pelts by removing the unwanted components consisting of the proteinous products, epidermis, short hair and the scud Interfibrillary proteins are also removed during the process to obtain proper grain texture and achieve softness and flexibility in the finished leather in bating, the proteolytic enzymes based on mostly trypsin are used

Pickling is carried out to bring down the pH to 2.5-30 so as to get quicker penetration and more uniform distribution in chrome tanning, The pelt is treated with a mixture of formic, sulphuric acid, and sodium chloride Sodium chloride is used to suppress the acid swelling Special non swelling acids are also used at SLW for pickling which enhances the quality of hides

The process used for tanning of skins and hides are mainly chrome, vegetable tanning & chrome free Chrome tanning is started at a pH around 2.8 and finally after ensuring complete penetration, the pH is raised to 3.8-4.0 during basification to complete chrome tanning. SLW specializes in baby calf process which is usually vegetable based further we also offer Chrome free leathers.

After main tanning the wet blue is selected for quality and stored in wet blue storage under special conditions to preserve the wet blue.

Samming is a process where moisture is reduced in the wet blue by passing through samming machine. This is done so hides are ready for splitting.

After samming, leather is split into two layers with the help of sharp blades splitting machine Upper one is grain layer and lower is split layer which is by product of leather and sold as it is. SLW have two splitting machine for this purpose

Leather is shaved from flesh side on its required gauge and sent to trimming department where they trim the excess part of hide SLW has four shaving machines

Leathers are retanned, dyed and fat liquoring

to achieve required colour and temper.

The dyes used in leather can be classified into

* Acid dyes

* Metal complex dyes

SLW have three big size Vacuum machines with three plate to get better and faster production. Vaccum dryer reduces the moisture of leather by suction pump and heating plates to get flat and smooth grain surface. SLW has the latest technology heat pump low temperature vaccum machine.

SLW has chain conveyer hang drying system. With this system drying is more gentle and uniform with minimal energy consumption. After drying leather it is sent to conditioning room for overnight conditioning. We keep certain moisture level in leather to prevent fiber sticking and to be able to withstand Dry Mechanical Operations.

Molisa is a process where leather is passed through staking machine to achieve softness in leather

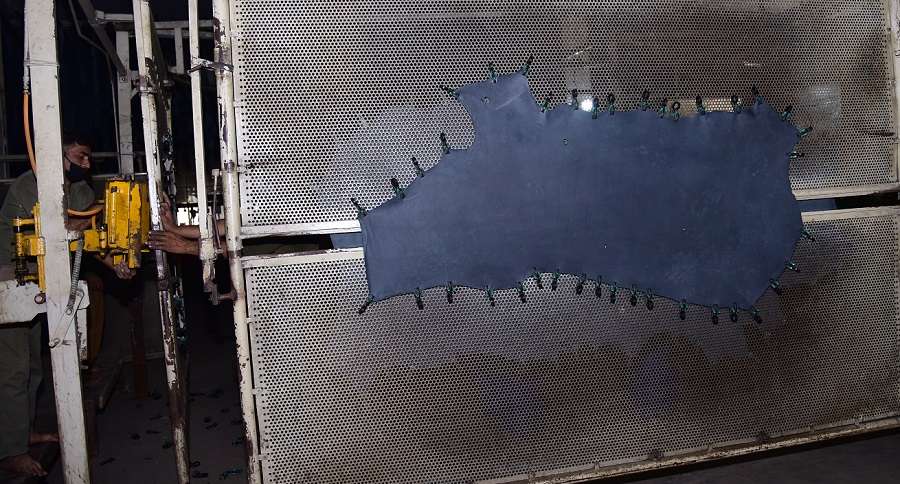

Four toggles work in process to increase the productivity of tannery. In toggle machine leather is stretched to its fiber capacity and kept in heat (40-50C) for about 30 min to increase area and grain smoothness. The toggle dryers run on thermal oil heaters which work on solar energy

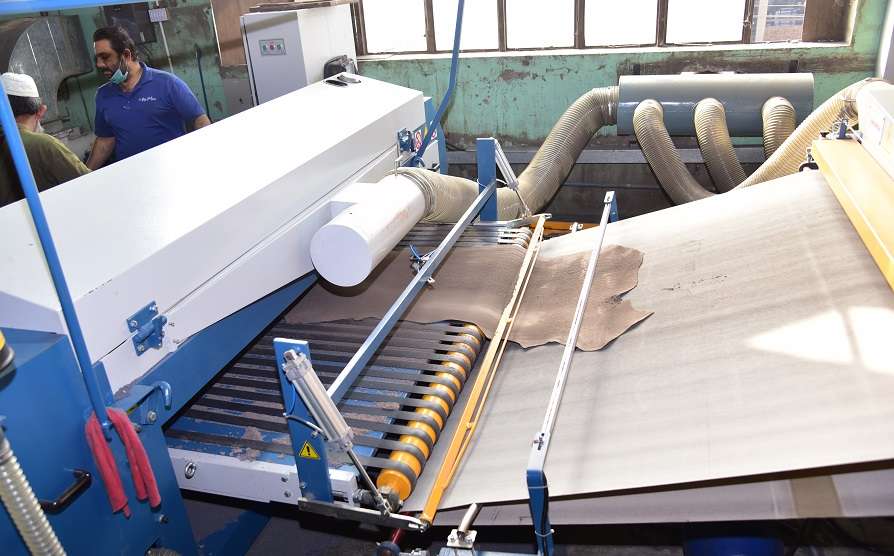

SLW has 4 buffing/snuffing machines specially for Nubuck articles which is in great demand

SLW has 4 dry milling drums which also have moisture and humidity control and two tumble dryers.

Finishing of leather consists in the application of a film forming material to the grain to provide aesthetic appeal and

to improve the sale value of the leather. It also provides surface protection against rubbing, abrasion and Staining

and hence the cutting value is also very much enhanced.

SLW has 2 floors for finishing. On 1st floor we have one big spray plant and two small spray plants also we have 2

roller coaters and one syncro machine. On 2nd floor we have one big spray plant and one small spray plant

and one Roller coater. This entire department is in dust free zone to avoid dust settling on leathers.

During finishing and in between spraying below processes are also carried out as per requirement.

In selection department each skin is checked for quality/selection, after checking trimming the finished leather is sent to packing department where it is measured on measuring machine and then packed In packing we have three measuring which includes the largest measuring machine by GER.